|

|||

|

|||

DMS Incorporated

570a Telser Road

Lake Zurich,

IL 60047

U.S.A.

Phone:

847-726-2828

Toll free:

800-655-7882

Fax:

847-726-9292

DMS, Inc.

Rotary die maker.

Rotary dies for

economy, speed

and efficiency. Hot stamping equipment,

hot stamping dies.

Flexo press accessories.

Site Map

Site design and search engine optimization by:

![]()

| High Speed Rotary Hot Stamping Systems |

|

|

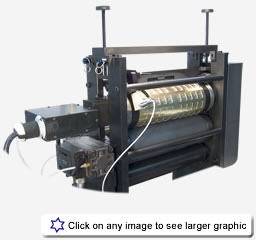

DMS FR Series: |

The heavy-duty drop in system that operates like a die instead of a print cylinder ! |

FR Series Exclusives : Back

• The industries only system that incorporates an assist roll and bearers and operates like a die instead of like a

print cylinder

• Die preload pressure is applied to bearers, not to journal ends

• Automated and programmable hot stamp shaft cooling ensures precise temperature control with any material

and for any press condition

• Automated foil nip and impression control is independent of die preload pressure

• Features the DMS "FPC" Foil Printing and System Controller. The FPC utilizes 32 programmable parameters

for optimum performance under any conditions and for all processes. The FPC features advanced adaptive and

predictive control and operation software and continuously monitors both die and press conditions

• Performance, Speed, Quality, Reliability, Flexibility. Our customers who have both our systems and our

competitors, consistently say ours perform better. We deliver better results with more control for more

applications and materials at higher speeds with less downtime, period!

• Experience. DMS has 30 years experience in rotary hot stamping systems, tooling and applications. We are

most likely familiar with your process and we will apply our knowledge and experience to your benefit.

• Complete process control capability. Our FPC Foil Printing and System Controller was custom designed

specifically for the demands of high speed rotary hot stamping, heat sealing and hot laminating

• Compact press top system controller. Our FPC is small and portable and easily movable around the press.

• Accepts all tooling. Our system accepts any conventional hot stamping dies, our exclusive ColdPocket

continuous surface hot stamping / heat sealing dies, magnetic cylinders, and flexible sheet dies

• High performance electrical heating. Our systems feature very high output electrical heater cores designed

specifically for hot stamping. They offer up to twice the power of our competitors electric systems! Our systems

are unique in that they also incorporate integrated hot stamp shaft cooling. When compared to hot oil, our

systems are safer and less expensive to

purchase, operate and maintain all while having no penalty in

performance or process stability

FR Series Specifications: Back

• For narrow to mid web presses and machines up to 30 inches wide

• Foil nip control independent of die pre-load pressure

• Lateral running register control

• Integrated forced air hot stamp shaft cooling. Provides tighter temperature control than hot oil systems in most

cases.

• Sealed oil bath bearing assembly on most units

• Wetted metallic slip ring assembly

• Most powerful heaters. Typically 300 watts per inch of web width

• Complete system includes:

• DMS FPC foil printing and system controller

• Hot stamp shaft assembly

• Hot stamp eccentric impression roll assembly

• Hot stamp die assist assembly

• Non-contact temperature sensor including articulated mounting arm

• Air lines, power cables and press run state condition cables

FR Series Options: Back

• Built-In electronic load cell option for TorKit digital die pressure gauge

• Remote operator interface

• Ebonite, Hypalon, Silicone, Steel and Chrome Steel base roll options

• Preload, Nip, and Temperature monitoring for your validation requirements

Typical Applications:

Back

• Hot stamping including foils, magnetic tapes, security seals and tapes

• Hologram applications, registered or wallpaper type

• Heat sealing including pouches, bags, sachets, and holders

• Over wrapping of direct mail, point of sale items etc.

• Hot laminating

• Thermal die cutting or forming

See Our FR Series in operation at Label Expo 2008: