FV Series Features and Advantages:

♦ More Applications. The system can be used for any rotary application that requires heat. These include hot foil stamping, magnetic tape stripes, heat sealing and welding, hologramsand security applications, hot laminating, heated rollers, specialized applications and more.

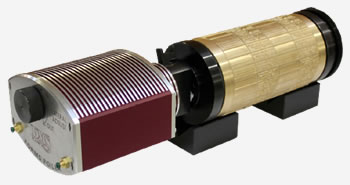

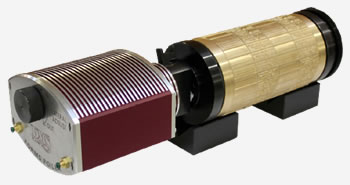

♦ New Technology. FV Series introduces Multiple Die Shaft technology, allowing you to easily change hot stamp shafts and mandrels and run a variety of hot stamping die technologies. Optional hot stamp shafts are available to run Ikela and other legacy hot stamping system dies.

♦ Experience. FV Series is our 5th generation drop-in type hot stamping system and benefits from our 30 plus years of designing and manufacturing rotary heated systems.

♦ Performance, Speed, Quality, Reliability, and Flexibility. Customers with multiple vendor experience consistently say our system performs better. FV series delivers better results, more control, for more applications and materials, at higher speeds, and with less downtime, period!

♦ Complete Process Control. Our new and exclusive FPC5000 Foil Printing and System Controller was designed specifically for the demands of high speed rotary heated applications and features system and process control capabilities not available on other systems.

♦ High Performance Heating. We use very high output electrical heaters designed specifically for our systems. These provide up to twice the power of our competitors electric systems! The FV system is able to maintain and control very high sustained temperatures, with large mass dies, well above those required for decorative foil stamping. Our systems outperform any competing hot oil, encapsulated oil, or electrical heated systems.

♦ Die Shaft Cooling. Our FV Series features forced air hot stamp shaft and mandrel cooling. This provides more precise overall temperature control, with faster routine temperature changes, and faster die cool down that competing electrical, hot oil, or encapsulated oil heated systems.

DMS, Inc. The world leader in rotary hot foil stamping systems and rotary hot foil stamping dies.